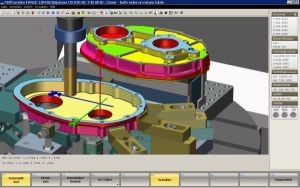

With TopTurn and TopMill NC programs can be created with dialog input in an interactive operation mode for any desired CNC control combined with an MTS 3D machine model. Since the workpiece and the tool cutting geometry are, however, not sufficient for a realistic simulation with collision monitoring, the precise tool representations with cutting edge, holder and tool mounting, the workpiece clamping devices as well as relevant machine components (such as neighboring tools, tailstock, counter spindle, dividing heads, …) must also be used for collision monitoring. Thats why MTS offer you the best solution .

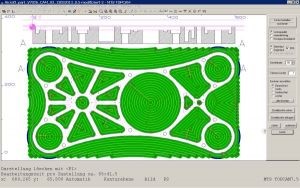

TopCAM2D is a programming system for turning and milling, integrated into a 2D-CAD-system for 2½D multi-sided milling machining and complete turnmill machining with driven tools and opposite spindle. The CAM section uses the TopCAT tool management and the MTS set-up dialog.

Further info: https://www.mts-cnc.com//index.php/en/44.html

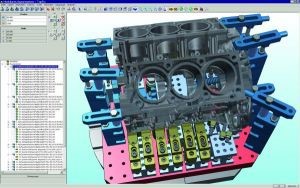

TopCAM3D as extension of TopCAM2D, supplements the MTS product TopMill and TopTurn with a 3D programming system for prismatic 2½ D multi-sided and complete machining with 5 axes machining centers. The workpiece data is imported in 3D-step format.

Further info: https://www.mts-cnc.com//index.php/en/46.html

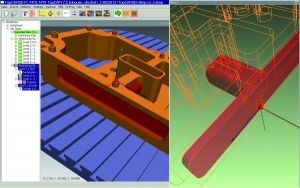

In addition to standard clamping devices for setup, as jaw chucks, clamping between centers or parallel vices, the modular clamping system TopFix can be used in order to clamp a workpiece directly onto the machine table with supports, stops, clamps and clamping shoes, or to clamp a complex cast workpiece with clamping elements of a modular clamping system.TopFix allows you to quickly and easily design a workpiece clamping by means of a, interactive graphical process, for any given, prefabricated workpiece or free form raw part. The clamping is free of mounting errors and mounting collisions of the clamping components. Even very complex clamping tasks can easily be planned and accomplished.

Further info: https://www.mts-cnc.com//index.php/en/47.html

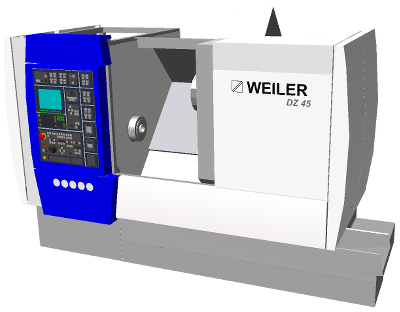

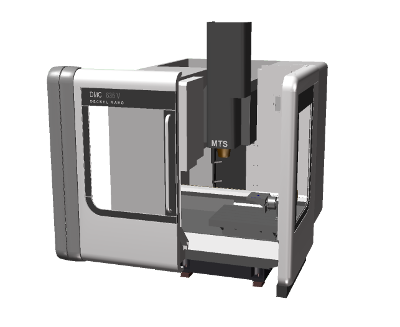

The MTS simulation software uses 3D models of machine tools, which emulate modern machining centers in all relevant details. These machine models consist of the NC axes kinematics to which the 3D CAD data of the machine tool components are attached in an internal MTS format. MTS offers already numerous models of current machines, built from original CAD data from the machine manufacturers (see the demo versions of TopMill and TopTurn). New machine models can be added.

Further info: https://www.mts-cnc.com//index.php/en/machine-tool-models.html