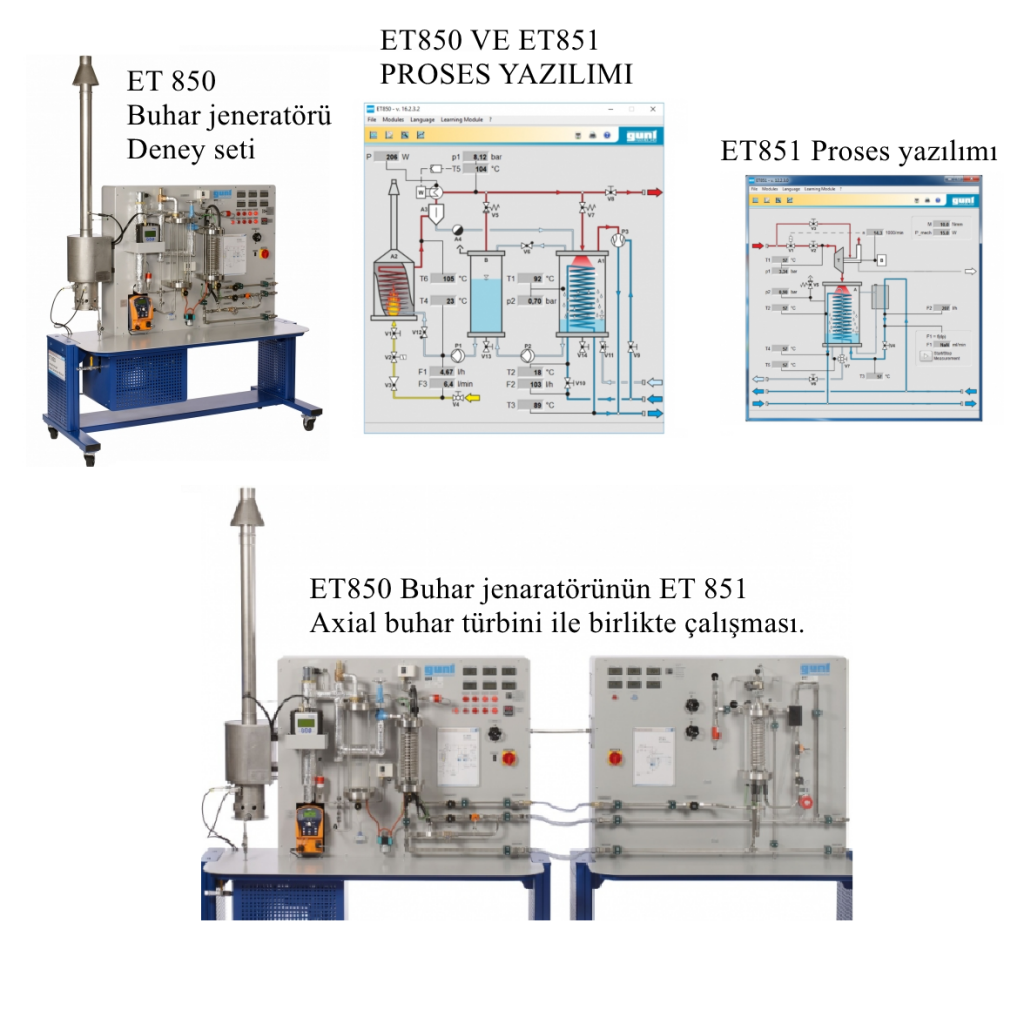

ET850

A steam generator generates steam which will later be used in drives for steam turbines or for heating. Steam generators and steam consumers together form a steam power plant. Steam power plants work according to the Rankine cycle which is still one of the most important industrially used cyclic processes. Steam power plants are mainly used for electrical power generation. The ET 850 steam generator and the ET 851 axial steam turbine together form a complete laboratory-scale steam power plant.

ET851

Steam turbines are turbomachines. In practice, steam turbines are mainly used in power plants to generate electricity. A distinction is made between turbines depending on the flow direction and state of the steam, the working process, and steam supply and discharge. The ET 851 experimental unit is a single-stage axial impulse turbine with a vertical axis. The steam required is generated by the steam generator ET 850. The turbine can be operated with saturated steam or superheated steam.

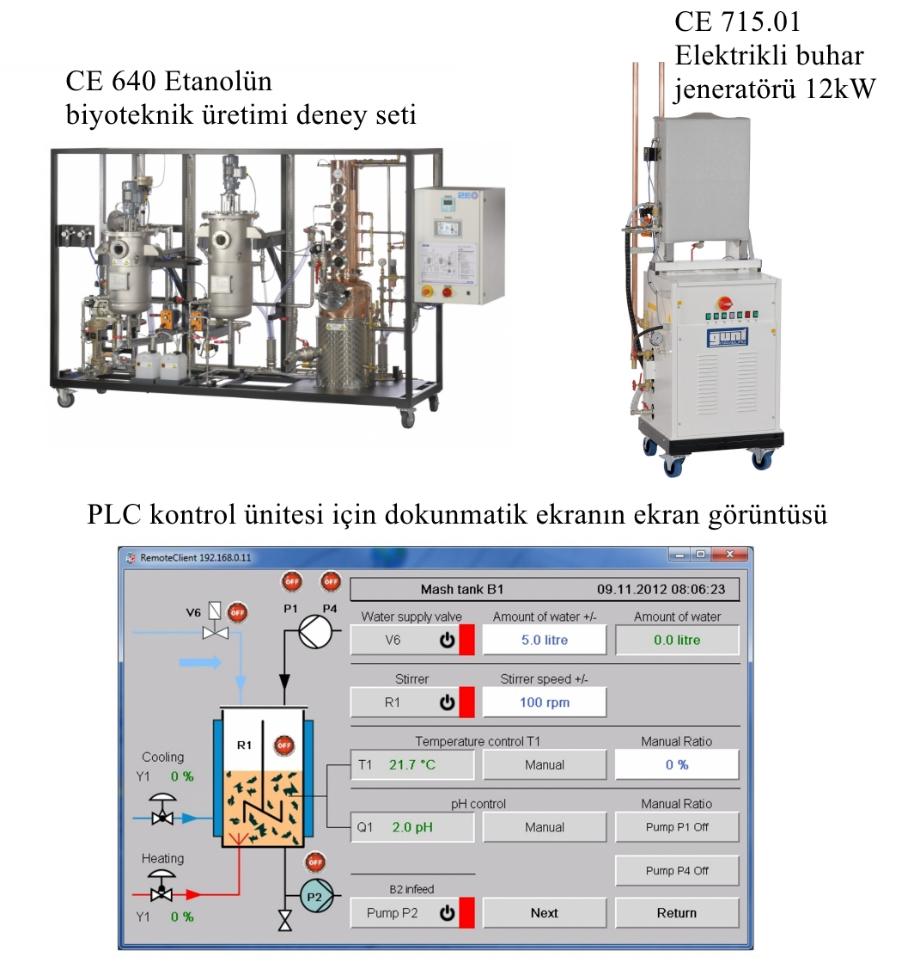

CE640

As well as its great importance for the chemical and foodstuffs industries, ethanol (alcohol) is increasingly used as a fuel. The CE 640 can be used to conduct realistic experiments for the production of ethanol from starch-based raw materials such as potatoes. The experimental plant consists of three main components: a mash tank, a fermentation tank and a distillation unit.

CE715.01

The CE 715.01 electrically heated steam generator is type tested and does not require specific permissions. The function is fully automatic. The short heat-up time until steam is produced allows elaborate experiments to be conducted in short periods of time. Extensive safety equipment ensures safe operation.

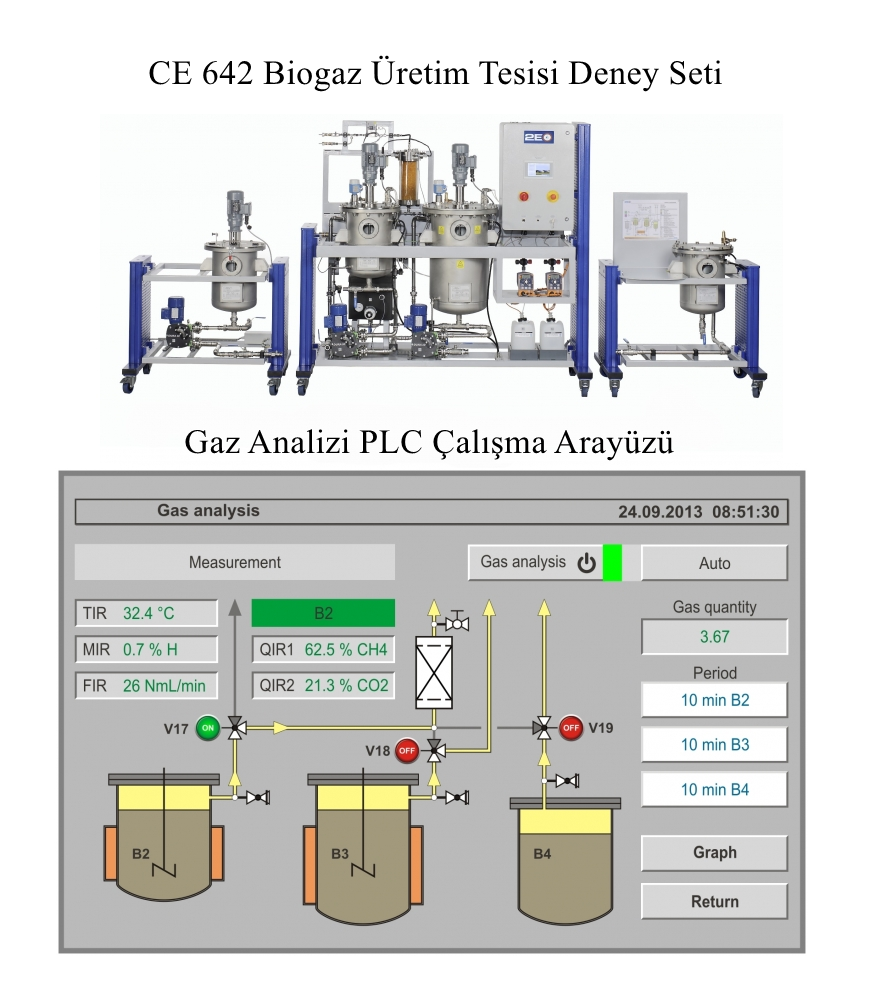

CE642

In a biogas plant, microorganisms biologically degradate the organic starting substances (substrate) under exclusion of light and oxygen. The product of this anaerobic degradation is a gas mixture which primarily consists of methane. This gas mixture is called biogas.The experimental plant CE 642 serves to demonstrate the generation of biogas in a practical manner. The substrate is a suspension of shredded organic solids. It is hydrolysed and acidified in the first stirred tank reactor. Here, anaerobic microorganisms convert the long-chain organic substances into short-chain organic substances. The biogas forms in the second stirred tank reactor in the last step of the anaerobic degradation. It contains mainly methane and carbon dioxide. This two-stage method enables the ambient conditions to be adjusted and optimised in both reactors separately. The digestate is collected in a separate tank.Temperature and pH value are controlled in both reactors. The resulting biogas is dried in a column. The column is filled with silica gel. Subsequently, the flow rate, humidity, methane content, carbon dioxide content and temperature of the biogas are measured. The system is controlled by means of a PLC which is operated via a touch screen. The measured values can be transmitted to a PC via USB and analysed with the GUNT software.

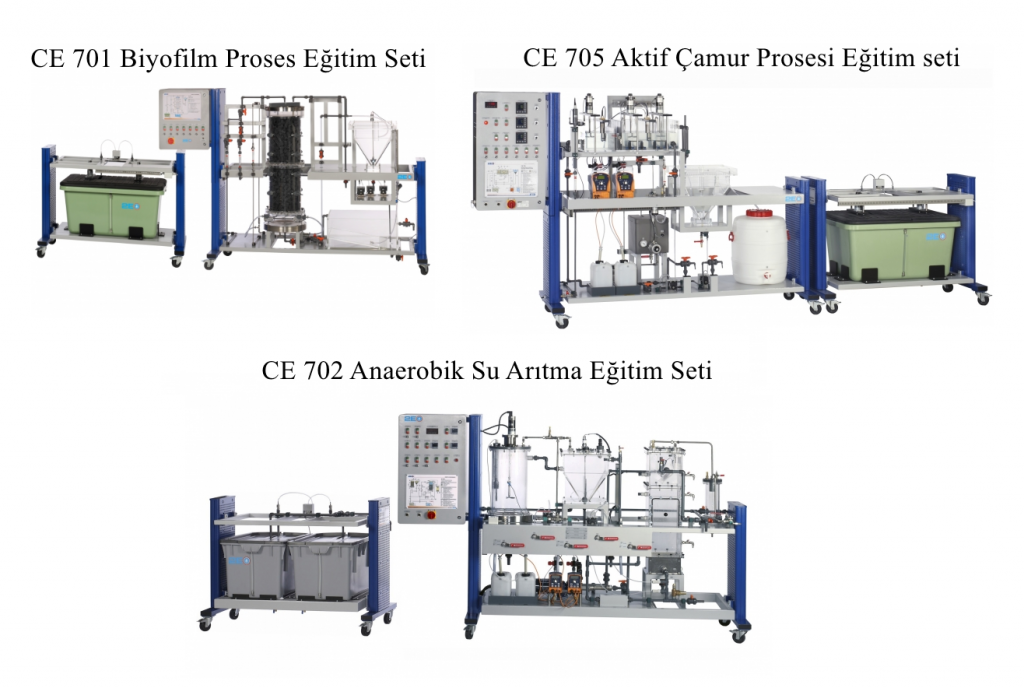

CE701

Fixed biofilm processes are used in the biological treatment of wastewater. Trickling filters are based on these processes.A pump transports the wastewater from the supply unit to the upper end of the trickling filter. The wastewater drops down on the trickling filter using a rotary distributor. In the trickling filter there is a fixed bed consisting of special carrier material. On this carrier material there is a thin layer of microorganisms (biofilm).

CE705

The activated sludge process is the most important biological process in water treatment. CE 705 enables this process to be demonstrated. A pump delivers raw water contaminated with dissolved organic substances (organic matter) into the aeration tank. Aerobic microorganisms (activated sludge) in the aeration tank use the organic matter as a source of nutrition, biodegrading it in the process.

CE702

CE 702 demonstrates the biological anaerobic water treatment. The trainer consists basically of two units:- stirring tank with secondary clarifier- UASB reactor. Both units can be used separately or in combination. This allows both a single stage and a dual stage operation mode.