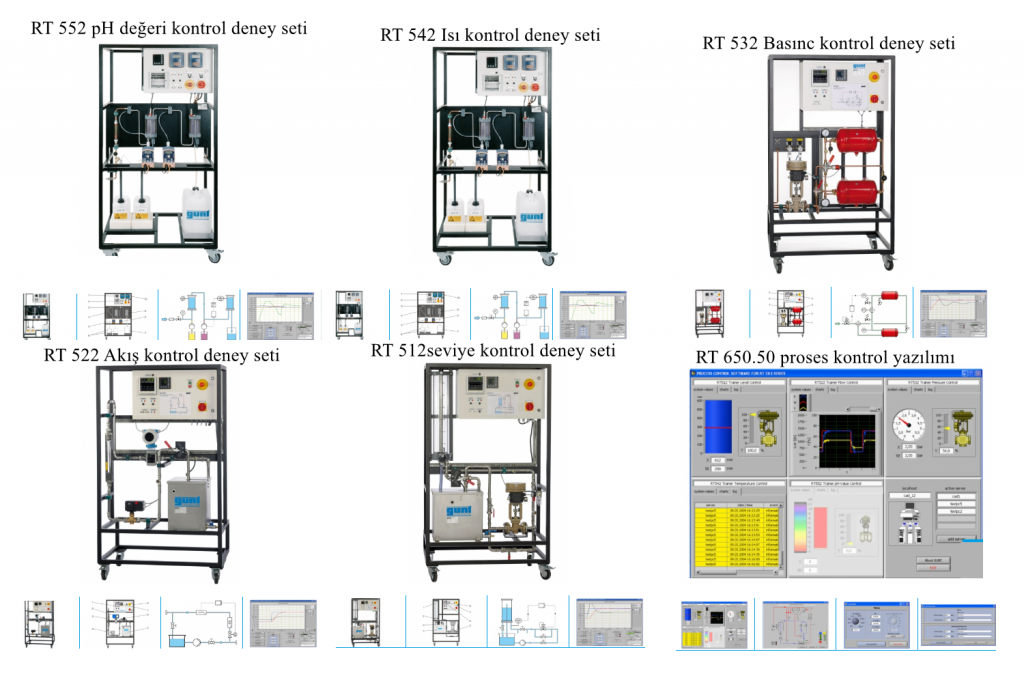

RT552

This trainer provides a comprehensive experimental introduction to the fundamentals of control engineering using an example of continuous pH control. A caustic solution is added to fresh water by way of a metering pump. The pH value of this solution is measured. The acid is then added to the solution as a neutralising reagent by way of a second metering pump. The chemical reaction occurs in a pipeline system.

RT542

This trainer provides a comprehensive experimental introduction to the fundamentals of control engineering using an example of temperature control.A circulating pump delivers water within a closed circuit. The flow rate of water can be adjusted by a hand-operated valve. The loop also contains a screw-in heater, a heat exchanger with fan, and three integrated thermocouples for temperature measurement.

RT532

This trainer provides a comprehensive experimental introduction to the fundamentals of control engineering using an example of pressure control.The air pressure control system is a 2nd order system.

RT522

This trainer provides a comprehensive experimental introduction to the fundamentals of control engineering using an example of flow control.A pump delivers water from a storage tank through a piping system. The flow rate is measured by an electromagnetic sensor, which permits further processing of the measured value by outputting a standardised current signal.

RT512

This trainer provides a comprehensive experimental introduction to the fundamentals of control engineering using an example of level control.A pump delivers water from a storage tank to the transparent level-controlled tank. The liquid level is measured by a pressure transducer installed at the base of the level-controlled tank. The controller used is a state-of-the-art digital industrial controller.

RT650.50

The RT 650.50 process control software (SCADA) was developed specially for the RT 512 – RT 552 series of trainers. It can automatically detect which units are connected for operation. Up to five units can be connected simultaneously. The program and the trainers communicate via Profibus DP modules. Changes to the software are transmitted to the controller of the relevant trainer.

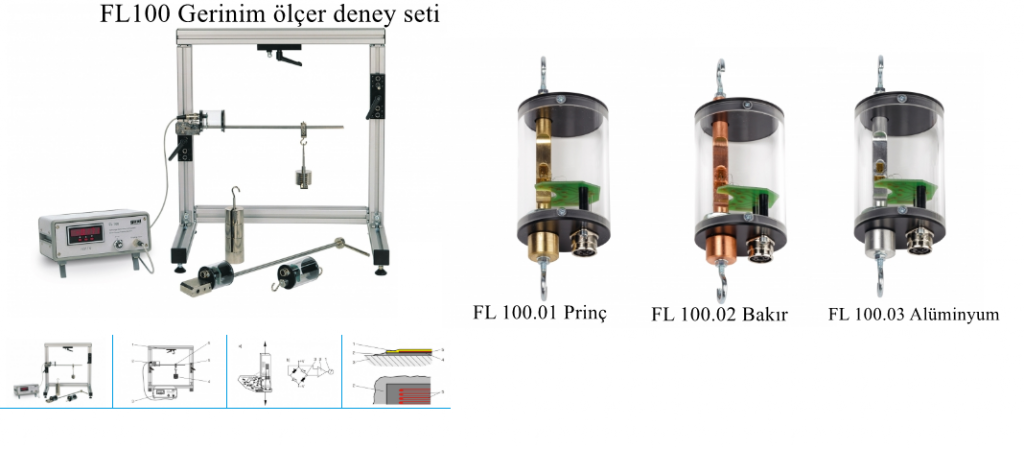

FL100

Strain gauges are used extensively in sensor systems to detect forces, moments and deformations.The FL 100 experimental unit provides a wide-ranging introduction to the fundamentals of measurement by strain gauges. Three test specimens for tension, bending and torsion are each fitted with four strain gauge measuring points. The strain gauges are wired in the full bridge. The specimens are loaded incrementally allowing for the strain reading to be sequentially monitored.

FL100.01, FL100.02, FL100.03

This test specimens for tension is available as accessory for FL 100 Strain gauge training system.

PT500

In order to avoid serious damage to machines and to carry out maintenance on time, the condition of the machine must be known. The state of a machine or machine parts can generally be judged well in terms of the type and size of its vibrations. The machinery diagnostic system can be used to simulate certain types of damage and investigate its effects on the vibration spectrum.The PT 500 base unit permits vibration measuring exercises (measurement of vibration displacement, velocity and acceleration in the time/frequency range). Field balancing of rigid rotors and alignment of shafts can also be practiced.

PT500.04

The computerised vibration analyser was developed specially to support analysis of machinery diagnostic experiments of the PT 500 series. The analyser can also be used in many other vibration experiments (such as TM 150).

PT500.05

Many vibration phenomena can only be achieved when the system is under load. The brake and load unit is used to generate vibration as a function of torque, e.g. in toothed gearing mechanisms or electric motors.

PT500.11

Cracks due to material fatigue are very dangerous for rotating machines. Early detection of any crack is therefore essential before permanent rupture and often fatal consequences can occur. The crack influences the vibration behaviour of the shaft by changing its rigidity. Using suitable analysis software, this change can be registered and inspection of the machine organised in good time.

PT500.14

When properly designed, manufactured, and correctly set; belt drives are low-maintenance, low-noise, long-life drive units. It is important that the belt should not vibrate and/or slip.The PT 500.14 accessory setup can be used to investigate conditions that cause vibration or slip.

PT500.15

The PT 500.15 accessory setup is used to simulate typical damage to gears and study its effects on vibration behaviour. Various gear sets with tooth damage are supplied for this purpose

PT500.10

This accessory setup enables the response of an elastic rotor to unbalanced excitation to be studied. The subcritical, supercritical and resonance running states can be demonstrated. A comparison of the orbits (path curves) in the subcritical and supercritical range is of particular interest.

PT500.12

Vibration analysis is a key tool in estimating the condition of a roller bearing. The slow change in the vibration spectrum provides indications of the remaining life of a bearing and can be used as a criterion for its replacement. The spectral distribution can deliver accurate information on the type and location of the damage.

PT500.13

Rotating machine elements are interconnected by way of couplings. A coupling exhibiting production or assembly faults generates machine vibrations which can be analysed to give an indication of specific faults or damage.The PT 500.13 accessory set can be used to simulate various faults and investigate their effects on vibration behaviour

IA520

The IA 520 training system presented here represents a fully functional CIM cell (CIM = Computer Integrated Manufacturing). The system allows an automated manufacturing process to be created. The IA 520 demonstrates the basic processes of handling (robots), manufacturing (CNC machining), and control (PLC). An overhead robot on a travel unit supplies two CNC machines with raw parts taken from a magazine. The machined dimensions of the parts are checked in an inspection station before the parts are placed in a finished parts store. Defined planning and control data is used to control various machines. The relevant data is stored in a software program, and is processed by the control units of the individual machines. A PLC system monitors and controls the process. The manufacturing cell is equipped with all necessary sensors and control devices.

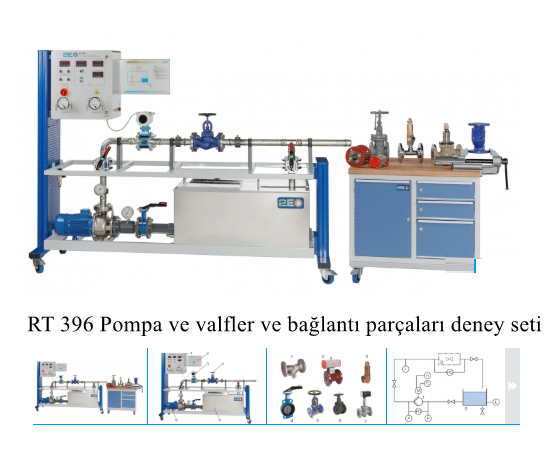

RT396

RT 396 allows the characteristics of different valves and fittings to be compared. The typical kinds of valves and fittings are represented by a ball valve, a butterfly valve, a gate valves, a shut-off valve and a control valve. A safety valve and a dirt trap are also investigated. All valves and fittings are flanged, and can be installed in a pipe section with variable length. The pipe section is part of a closed water circuit. Pressure measurement points upstream and downstream of the valve and fitting under test are linked by a differential pressure manometer. This manometer is fitted with a pressure switch which activates a warning lamp if the pressure difference becomes excessive, such as when the filter is clogged. An electromagnetic flow rate sensor permits precise recording of the flow rates.

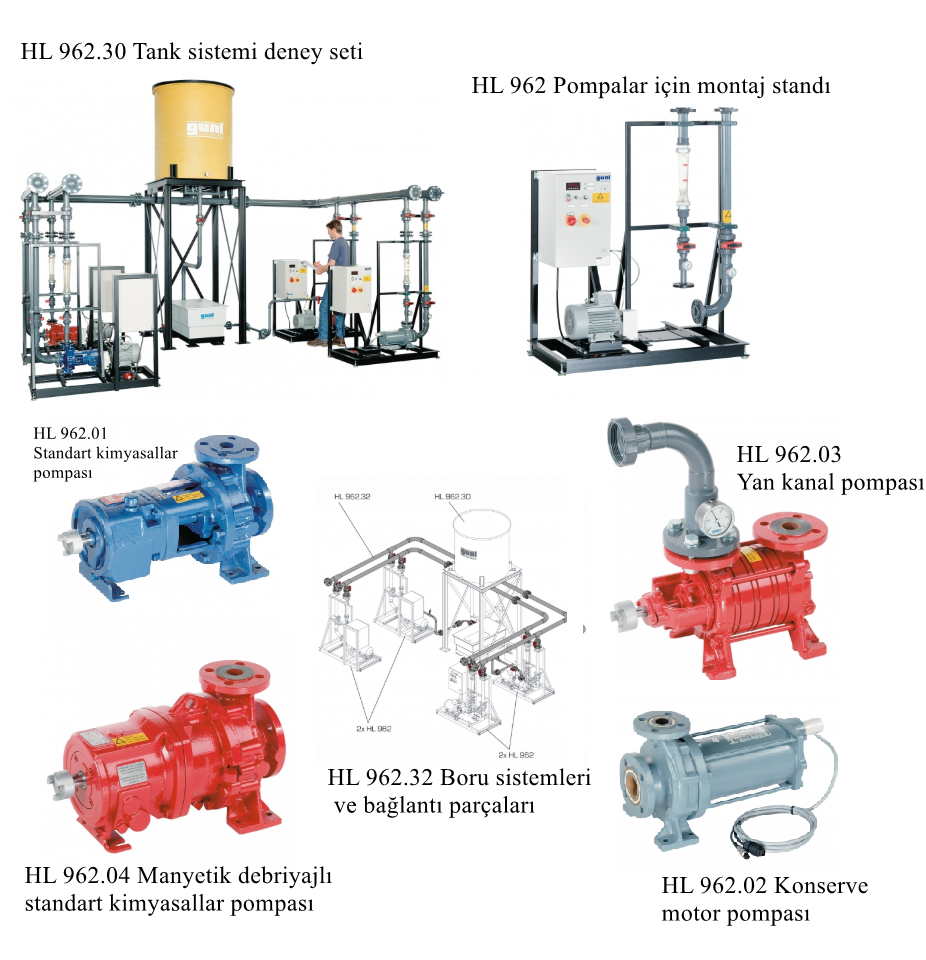

HL962

The individual steps for repairing driven machines such as pumps are: removal and installation of pumps for inspection, repair or replacement; aligning the drive and commissioning and checking the pump, e.g. for leaks.In conjunction with the HL 962.30 tank system, the HL 962.32 connecting pipes and one of the four HL 962.01 – HL 962.04 pumps, the HL 962 assembly stand forms a complete training system for complex piping and plant systems. The training system forms a closed water circuit.

HL962.30

The HL 962 assembly stands are connected with piping elements from HL 962.32 to form a complex piping and pump system. The tank system HL 962.30 is required so that the system can operate as a closed process.The tank system consists of a large high-level tank with a mounting frame, a low-level tank and connections with shut-off devices to the PVC piping system HL 962.32.The high-level tank has a capacity of approximately 1,5m³ of water. A manometer close to the base of the tank measures the base pressure, thereby indicating the fill level. The high-level tank supplies the intake pipes of normally primed centrifugal pumps, and ensures an adequate inflow head. Its inlet and outlet distribution points are located at a height of about 2m.

HL962.01

The standard pump used here is a centrifugal pump commonly used in the chemical and process engineering industries.

HL962.02

Canned motor pumps are used primarily in process engineering to pump aggressive, toxic, fire-hazard, explosive, delicate or volatile liquids (such as liquid gases).

HL962.03

Side channel pumps are self-priming centrifugal pumps, and are in widespread use. They can attain relatively high pressures at low flow rates. They are able to intake and deliver liquids containing gases.

HL962.04

Magnetic drive pumps are used primarily in process engineering to pump aggressive, toxic and flammable liquids. Leakage of such liquids could result in major problems. Its design means it is completely leak-tight, even at continuous operation and under difficult usage conditions.

HL962.32

The accessory set includes all pipes, fittings and connecting elements required to create a complete experimental setup for assembly and maintenance exercises.A total of up to four HL 962 assembly stands can be connected to the HL 962.30 tank system.